Why Mold With Expandable Polystyrene

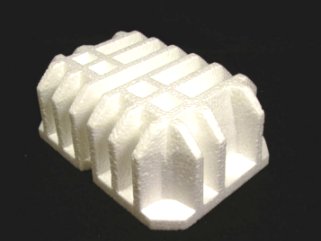

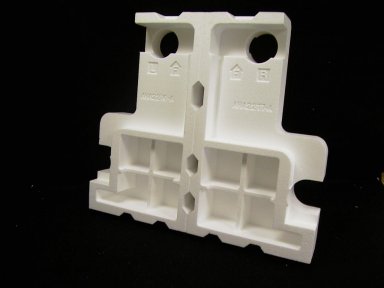

Packaging SuperiorityEfficiencyTo secure products for shipping, no other packaging provides the customized fit of EPS molded foam. Labor SavingOther packaging inserts only approximate product dimensions, often requiring complicated and time consuming assembly. Lightweight molded EPS foam, however, is quickly and easily secured to products, minimizing costs of design, assembly and distribution. Superior InsulationDue to its unparalleled insulation properties, EPS foam packaging is highly resistant to heat flow. As a result, many temperature sensitive products such as electronic components, pharmaceuticals, chemicals and perishable goods are packaged almost exclusively with EPS foam. Dust freeEPS foam packaging provides superior cushioning and insulation for even the most delicate items. And, it will not significantly increase product weight or scratch delicate product surfaces. Nearly static free, EPS is easily treated for additional static protection in critical applications.

Security and PresentationSecure ProtectionEPS molded foam packaging provides a secure fit with no mess. It's solid, rigid structure helps prevent dangerous shifting during product shipment. Well-fitting custom EPS foam packaging offers minimal compressability, repeated handling and durability. PresentationCustom EPS foam packaging helps define quality products. Logos and data are easily molded into EPS packaging. EPS foam will not attract moisture or remove adhesive labeling. When a product arrives at its destination, it will be intact and ready for use.

|

|||

| Home | Why Topper | Specialty Fabrication | Why EPS | Molding Capabilities | Recycling | Contact Us | |||

| Our Goal Our goal is to produce superior products that exceed our customers' standards for quality, lead time, and innovation |

|||